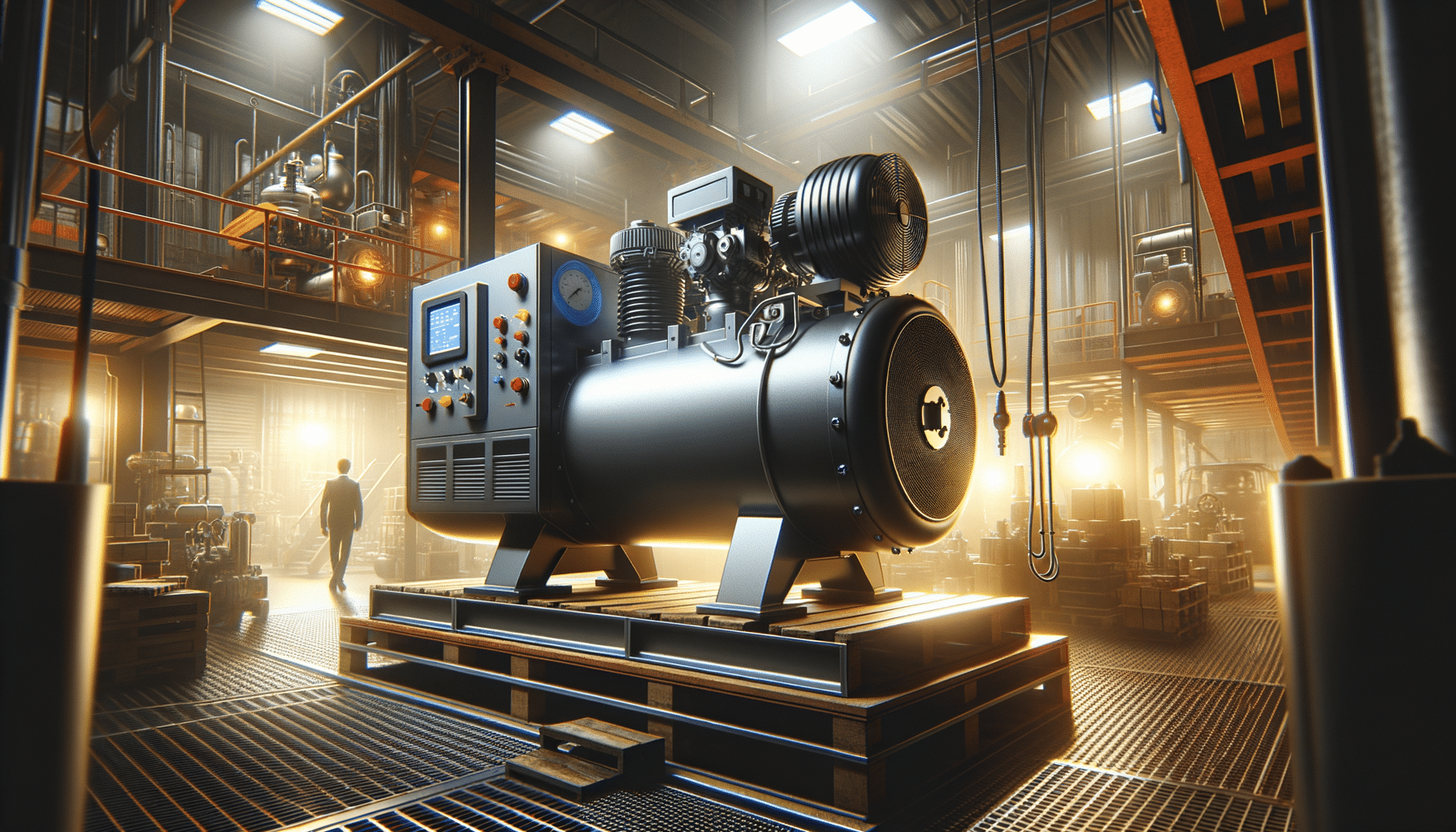

Industrial Air Compressor Options for Your Business

Understanding Industrial Air Compressors

Industrial air compressors are vital tools in many sectors, providing the power necessary to operate a variety of machinery and tools. Unlike their smaller counterparts, these compressors are designed to handle larger volumes of air at higher pressures, making them suitable for heavy-duty applications. When considering an industrial air compressor for sale, it’s essential to understand the different types available, such as rotary screw, reciprocating, and centrifugal compressors.

Each type has its own set of advantages. Rotary screw compressors, for instance, are known for their continuous duty capabilities and lower maintenance needs. Reciprocating compressors, on the other hand, are often praised for their high pressure output and versatility. Centrifugal compressors are typically used in large-scale operations due to their ability to deliver a continuous flow of air at a consistent pressure.

Choosing the right type depends largely on your specific needs, including the required pressure level, the volume of air needed, and the operating environment. It’s crucial to assess these factors carefully to ensure the compressor you select will meet your operational demands efficiently.

Key Features to Consider

When evaluating industrial air compressors for sale, several key features should be taken into account to ensure optimal performance and efficiency. First and foremost, consider the power source. Compressors can be powered by electricity, diesel, or gasoline, with each offering distinct benefits and drawbacks. Electric compressors are typically quieter and more environmentally friendly, while diesel and gasoline models offer greater portability.

Another critical factor is the compressor’s capacity, which is usually measured in cubic feet per minute (CFM). This indicates the volume of air the compressor can deliver at a given pressure. It’s important to select a compressor with a CFM rating that matches or exceeds the requirements of your tools and machinery.

Additional features to consider include the compressor’s duty cycle, which refers to the percentage of time the compressor can operate without needing to cool down, and its noise level, which can impact the working environment. By evaluating these features, you can ensure that the compressor you choose will meet your operational needs efficiently and effectively.

Assessing Your Business Needs

Before purchasing an industrial air compressor, it’s essential to conduct a thorough assessment of your business needs. Consider the specific applications for which the compressor will be used, as this will influence the type and size of the compressor required. For instance, a manufacturing facility with multiple machines may require a larger, more powerful compressor than a small workshop with fewer tools.

Additionally, consider the working environment. If the compressor will be used in a location with limited ventilation, an electric model may be preferable due to its cleaner emissions. Conversely, if the compressor needs to be moved frequently between job sites, a portable gasoline or diesel model might be more suitable.

Finally, consider your budget. While it’s important to invest in a high-quality compressor that will meet your needs, it’s also crucial to consider the long-term costs of ownership, including maintenance, energy consumption, and potential repairs. By carefully assessing your business needs, you can make an informed decision when selecting an industrial air compressor.

Maintenance and Longevity

Proper maintenance is key to ensuring the longevity and reliability of your industrial air compressor. Regular maintenance tasks include checking and replacing air filters, monitoring oil levels, and inspecting hoses and connections for signs of wear or damage. By adhering to a consistent maintenance schedule, you can prevent costly breakdowns and extend the lifespan of your compressor.

It’s also important to follow the manufacturer’s guidelines for maintenance and operation. This includes using the recommended type of oil and ensuring that the compressor is operated within its specified temperature and pressure ranges. Failure to adhere to these guidelines can result in reduced efficiency and increased wear and tear.

In addition to regular maintenance, consider investing in a service plan with a reputable provider. This can provide peace of mind, knowing that your compressor is being serviced by professionals who are familiar with its specific requirements. By prioritizing maintenance, you can ensure that your industrial air compressor remains a reliable and efficient asset for your business.

Making the Final Decision

Choosing the right industrial air compressor for your business is a significant decision that can impact your operations for years to come. By taking the time to research the different types of compressors available, assess your specific needs, and evaluate key features, you can make an informed choice that will enhance your productivity and efficiency.

Remember to consider the total cost of ownership, including initial purchase price, maintenance, and energy costs. This will help you select a compressor that not only meets your operational requirements but also fits within your budget.

Ultimately, the right industrial air compressor is one that aligns with your business goals and supports your long-term success. By following the guidance outlined in this article, you can confidently select a compressor that will serve your business well into the future.